Lots of Likes on Instagram: How You Can Quickly Increase Popularity

How to grow Popularity with your target audience Whether you are sharing pictures of your adorable pet or are advertising a new product, there is a certain thrill when somebody

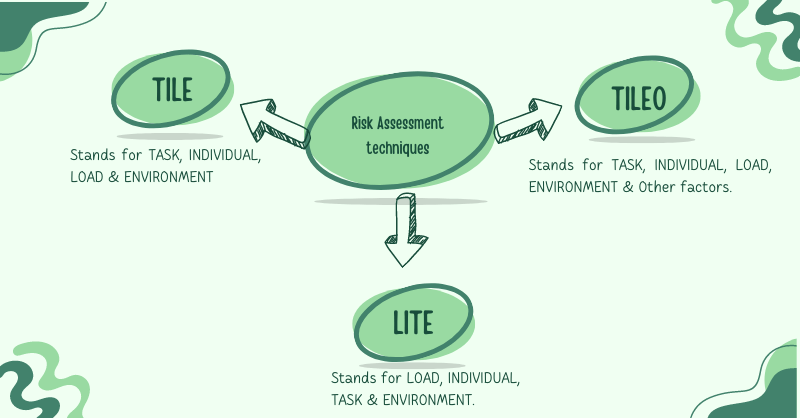

TILE, LITE and TILEO. These acronyms denote Task, Individual, Load, Environment, and Other

factors. They are used as a fast and practical method of evaluating tile manual handling risk.

TILE denotes Task, Individual Load, and Environment. It is associated with the Tile Manual Handling training. Besides, it aims to assist you in conducting a manual handling risk assessment.

TILEO is an acronym used as an effective method of evaluating tile manual handling risk. It stands for:

LITE is an alternative acronym to TILE that assists you in carrying out a Manual Handling Training Risk Assessment. The acronym stands for Load, Individual, Task, and Environment.

There are numerous risk factors when carrying out manual handling, lifting, moving or pulling tasks. Any one of them could result in serious injury. That’s why any organisation or company accountable for tile manual handling needs to ensure a thorough risk assessment before any such activity can occur. In doing so, bosses can weigh all the potential risks and take steps to mitigate them, assuring that the whole procedure can proceed safely and smoothly.

So, knowledge of the proper and safest techniques is essential.

This is where being familiar with TILE manual handling helps. From moving supplies, laundry, catering, equipment or waste to helping residents move. Poor moving and handling patterns can cause back pain, musculoskeletal disorders, and the inability to work.

Using TILE allows you to estimate the risks related to any tile manual handling activity. You can remove or significantly lower potential hazards by assessing the Task, Individual, Load, and Environment.

Moreover, it can confirm that the health and safety of all engaged people are protected and prevent injuries in the workplace. TILE was developed to make you consider each vital area of the job you’re doing to improve health & safety in the workplace.

TILE is an acronym that supports you in carrying out a tile manual handling risk assessment. Besides, TILE prompts you to evaluate each critical area of the work activity to improve health and safety. Regarding manual handling and tile handling training, the TILE acronym stands for Task, Individual, Load, and Environment. Therefore, workers and employers should evaluate these four factors before performing a manual handling job.

When considering tile manual handling risks, TILE helps you to conduct a manual handling risk assessment and remove or significantly lower any probable risks or threats that may impact the health and safety of any individuals related to the manual handling activity in the workplace.

Finally, understanding each possible risk of the manual handling activity can help save the employer and the employee from illnesses and injuries.

TASK is the first factor in TILE. You should assess the nature of the task that is about to take place. It is advised to reduce the risk facets as much as possible or reanalyse the task. These are some factors related to TASK. Ask yourself, does your work involve any of the following?

If most of your responses are positive or YES, then the risk is involved because of the TASK. You need to consider the task and any betterment that can be made.

The second factor is the Individual. It involves considering the individual or person who will carry out the tile manual handling task. This is the person who will be doing the manual handling. Their strength, abilities, training, and experience can affect them. Questions regarding INDIVIDUAL-

Each tile manual handling activity is somehow different. For example, a person may be capable of lifting and carrying in normal circumstances but not fit in a different environment. So, you should consider if there is anything exceptional or unusual.

Load is the third consideration in TILE. Load is the object or person that is being handled or transferred. In addition, the Load itself can have a significant impact on the risk level of the tile manual handling activity. Therefore, it is crucial to assess factors like the size, shape, weight or nature of the Load and how it might affect health and safety.

Getting positive answers defines a problem or consideration with the Load. Workers must carry out the load carefully. Moreover, if the Load can be separated or adjusted to make it easier to control, this can also be an excellent way to lower risk. Otherwise, you could consider robotic aids or a team lift for bulky or heavy loads.

The last factor to consider in TILE is the environment. Where tile manual handling will take place can also influence the safety of manual handling processes because it needs additional considerations such as wind, rain, ice, and temperature. In addition, these factors can impact the manual handling preplan. Questions to answer here are –

Indeed, planning your path according to the environment can help you safely transport the load without endangering the health and safety of anyone engaged.

TILEO is a slightly broader term with the addition of ‘O – Other Factors.’ TILEO implies Task, Individual, Load Environment and Other Factors. Yet, TILEO does not express a different meaning from TILE. Both hold the same purpose. For example, it can be the need for and impact of extra equipment required for a task.

Other factors include elements or factors that fall outside the four steps for tile manual handling but may be related to the task you are dealing with. When considering Other Factors, you should consider the following:

Besides, keeping an eye on the Other factors can help in completing the task more effectively and efficiently. Moreover, it can reduce risks by a significant margin.

LITE is another tile manual handling acronym of TILE. LITE is a rearrangement of the same critical factors as TILE and stands for Load, Individual, Task and Environment. Both terms have the same meaning, but the letters are in different order.

Indeed, LITE and TILE are both acceptable terms for manual handling – depending on which you find most comfortable and easy to remember. LITE denotes Load, Individual, Task and Environment. In addition, It aims to assist you in finishing your manual handling risk assessment. The LITE acronym stands for

L – Load. It also means the object’s size, shape, surface type and weight.

I – Individual. The strength of the individual executing the manual handling activity.

T – Task. Different manual handling activities include lifting or carrying, pushing, pulling, etc.

E – Environment. The area where the object is being moved.

It doesn’t matter whether employees use TILE or LITE in tile manual handling risk assessment as long as they assess each of the four critical stages for manual handling to lower the risk of injury.

TILE is a commonly used acronym for Task, individual, load and environment. People related to a task need to assess these four factors before executing a tile manual handling job. In addition, the term states that risk assessments should be done before employees participate in manual handling.

Moreover, TILE helps to remember the numerous areas that employees and employers should evaluate before determining whether a task is secure and safe to carry out. TILE is related to the four essential areas of manual handling:

Therefore, employers and employees can utilise TILE to evaluate a task’s risk or decide on the safest & secure way to handle a load.

Manual handling covers different activities, including pulling and carrying, lifting, lowering, and pushing. If employees do not carry out these tasks appropriately, they endanger themselves. As a result, there is a risk of injury. In addition, tile manual handling causes over one-third of all workplace risks and damages.

These contain work-related musculoskeletal disorders such as pain and injuries to legs and joints, arms and repetitive strain injuries of various types.

In other words, safe manual handling means that the rate of injury & danger is comparably lower. Manual handling is related to various activities, including lifting, restraining, throwing and carrying, pushing, pulling, and holding.

Moreover, it includes repetitious tasks such as packing, assembling, cleaning, typing, and sorting, using hand tools, related operating machinery and equipment, and handling and restraining animals. In other words, not all manual handling tasks are risky, but because most jobs involve some form, most workers are at risk of manual handling damage or injury.

In addition, some practices include good posture and lifting, keeping the load close to your waist, adopting a stable position, avoiding twisting your back or leaning sideways, and moving smoothly. As an example, don’t flex your back any further. Safe handling and lifting can help diminish the risks, yet research reveals that changing workplace methods is more acceptable to prevent tile manual handling injuries or other threats.

Suppose managers and these employees collectively do not take accountability and use measures to stop tile manual handling. As a result, accidents may happen, or they may develop illnesses affecting their health and quality of life. So, if measures are implemented, the likelihood and risk of these mishaps can be diminished, ensuring that employees stay safe in the workplace and maintain their fitness. These measures include the practice of secure manual handling.

Therefore, by enforcing these techniques, you should be able to prevent the vast majority of tile manual injuries in the workplace. With manual handling injuries being a common occurrence that results in many lost working hours, the importance of safe and correct manual handling techniques cannot be overstated.

Indeed, suitable tile manual handling courses, especially those tailored and bespoke to the exact loads and daily tasks performed by employees, are essential to good health and safety practices.

TILE is a commonly used acronym for Task, Individual, Load, and Environment. Before conducting a manual handling job, workers should consider these four factors. For example, lifting, pulling, pushing, carrying etc. In addition, If managers or workers do not consider these four factors appropriately, the risk will never be decreased.

Moreover, TILE deals with a task to its final destination, where workers carry the objective. Additionally, it solves the question that is a barrier to the goal. Therefore, many successful workers and companies emphasise utilising TILE at work.

Furthermore, TILE in manual handling is also significant because employers have a legal obligation to defend their workers involved in manual handling. Again, ensuring employees know TILE and the correct manual handling techniques will reduce workplace risk and prevent staff injuries.

Unfortunately, many people get injuries every day because they don’t know the proper manual handling techniques. Besides, More than 20% of non-fatal injuries in the workplace are caused by tile manual handling tasks that have gone inaccurate, with manual handling being the most significant cause of musculoskeletal disorders suffered by workers.

Manual handling injuries can include:

Hence, tile manual handling training can play a significant role in reducing injuries or risks at the workplace.

Manual Handling Operations Regulations 1992 (MHOR) are the primary legislation regarding manual handling. It was first implemented in 1992 and amended in 2002. These rules outline the duties employers and employees have when manual handling and give directions for the best ways to minimise or remove risk.

Moreover, the order of controls contained within the regulation describes that you first must avoid manual handling. You need to consider and reduce the risk when this is impossible.

The Tile Manual Handling Operations Regulations are the most significant regarding this protection area, sometimes mistakenly referred to as the ‘manual handling act’. In addition, this dedicated piece of legislation is created to help employers and employees manage, control, and ultimately decrease the risk of injuries that might come about from poor manual handling practices.

Finally, one of the essential elements of the legislation is that, when it came into force in 1993, it required employers to take action regarding manual handling and ensured that they committed to their workers.

MHOR describes how to identify, assess and manage the risks associated with all manual handling duties. It covers four primary areas of consideration:

MHOR also outlines the following three steps to diminish the risks:

First, avoid dangerous tile manual handling procedures as it is reasonably practicable.

Second, assess any unsafe manual handling operations that cannot be overlooked.

Third, reduce the risk of hurt or other injuries as reasonably as possible.

The Manual Handling Operations Regulations 1992 protects the following health and safety obligations appropriate both to employers and employees:

Firstly, employers are liable for assuring that all reasonably predictable threats related to manual handling actions have been accurately determined, assessed and managed to ensure the safety of their employees. It involves performing risk assessments for all possible hazards.

Secondly, employees are instructed to follow all health and safety guidelines sketched by the employer, use all tools and gear correctly, and confirm that their actions don’t risk themselves or others.

TILE, LITE & TILEO, Whatever the acronym, their ultimate motto or meaning is the same. In addition, These acronyms provide a framework to analyse a Task, Individual, Load and Environment to reduce risk at the workplace. Each factor is equally important as they deal with different issues related to a particular work.

It should be considered that the employer should assign tasks based on an individual’s capacity. It is easy to get injured when an employer works under pressure or is overloaded.

So, whether you follow TILE, TILEO or LITE, each acronym covers the most significant factors that can make a tile manual handling task riskier. Considering each of them and manual handling training can help keep all employees safe from potential risks and injuries.

Planning is considered the first task in any tile manual handling task. Ensure the object is lightweight, steady, and unlikely to shift or move. Remove obstacles to ensure your path is clear and space to lower the load wherever you move.

Plan the lift/handling activity. Where is the pack or load going to be positioned? Besides, use appropriate handling aids where possible. Ask yourself, will you need assistance with the load?

Consider resting the load mid-way on a bench or table for long lifts to recharge the grip. Consider relaxing the load midway on a table/bench for long lifts to change your grip. Will help be required? Are there tools that workers could utilise to assist the lift?

Do not lift or perform with more than you can effortlessly handle. If you feel uncertain, seek advice and get help.

The Manual Handling Operations Rules are the most significant about this protection area, sometimes mistakenly referred to as the ‘manual handling act’. Manual Handling Operations Regulations 1992 (MHOR) are the primary legislation regarding manual handling. It was first implemented in 1992 and modified in 2002.

MHOR sets out three main parts employers should follow wherever practicable: Avoid, Assess, and Reduce. Firstly, avoiding means that manual handling should be evaded entirely in any practical scenario. For example, if there may be a risk to a person’s health, the task should not be carried out if possible.

Secondly, employers must estimate any risky task workers can not avoid. The third and final point is to Avoid. It forms the bulk of the MHOR- reducing risk when manual handling tasks in the workplace.

To attain proper tile manual handling techniques, you should obey these seven fundamental principles when pulling, lowering, lifting, pushing, emptying, carrying or filling.

Firstly, confirm that the object is light enough to lift, stable, and unlikely to shift or reposition. Clear the obstructions- ensure your path is clear and there is room to lower the load wherever you intend to move it. If you feel doubtful, look for guidance or get help.

Secondly, keep your feet separated, giving a stable base for lifting. Standing apart gives you a firm base to begin your manual handling shifting. Your leading leg needs to be as far forward as is relaxing and, if possible, indicate where you plan to go.

Thirdly, be ready to move your feet when lifting so that you can maintain a steady posture. Wear footwear such as flip-flops, high heels or tight clothing that may make this more difficult. In addition, when raising from a low level, angle your knees, and ensure your back is straight, keeping its natural curve.

Fourthly, make sure to hold your arms within the boundary formed by your legs. While grabbing something, a hook grip is less rugged than keeping your fingers straight.

Raise your chin as you initiate the lift, assuring control of your head. Look forward, not down at the load, once it has been held securely.

Hug the load tight to the body. It should help you make a more robust and solid lift than gripping the load tightly with your hands.

Finally, If you have to put the load in a specific position, put it down first, then drive it into the selected place.

TILE is an acronym commonly used in manual handling to evaluate a particular weight-bearing task. It stands for Task, Individual, Load, and Environment and is a simple go-to strategy to help decrease injury when carrying any heavy object. Therefore, we should consider these four factors before executing every manual handling duty.

Individuals have varied physical capacities, and employers should assess them in their estimation. Firstly, this step demands managers to consider the personal abilities of those involved in the work, including the employee’s age, health disorders, the equipment they possess and whether they require specialist training.

Secondly, some tasks may require a person with a specific level of strength. In addition, others may not be suitable for particular individuals due to prior injuries they may have sustained. Looking at each individual’s physical capability before accomplishing any task.

Moreover, anyone with a known disability or injury should be evaluated individually. Furthermore, employers must conduct special inspections for young workers and those with poor vision, receded grip strength, disability, or pregnancy.

Keep your head up when handling. Look forward, not down at the load, once it is appropriately kept. In addition, avoid bending or leaning sideways. Finally, keep the load near your waist for as long as you can when carrying.

The most common consequence of manual handling incidents is injuries and pain in different body parts. Besides, manual handling is one of many interrelated risks for acute low back pain.

Manual handling is any action or activity that demands you to transport or carry a load by hand or force. Five manual handling tasks are lifting, lowering, pushing, pulling or carrying. Some manual handling tasks include lifting boxes, pulling or pushing trolleys, forming products, packing containers, lifting heavy instruments and tools, etc.

How to grow Popularity with your target audience Whether you are sharing pictures of your adorable pet or are advertising a new product, there is a certain thrill when somebody

As technology advances, smartphones become more functional. Today, they can be used for photography along with digital cameras. Moreover, you can use them for image editing. Background removal is one

In today’s highly competitive market, businesses strive to achieve the best return on investment (ROI) from advertising spend. With budgets under constant scrutiny, it’s crucial to adopt strategies that ensure

In today’s digital age, applying for jobs has never been more convenient – or more risky. With a few clicks, you can submit your resume and personal information to potential

What makes Mac different is not just the fact that it is a tool but a creative fellow traveler in the design career for many. Its definition of the hardware

Imagine the digital marketplace as an ever-expanding universe, with billions of stars shining brightly, each representing an online store striving for attention. In this cosmic competition, Magento 2 hosting emerges as

No more than 50 active courses at any one time. Membership renews after 12 months. Cancel anytime from your account. Certain courses are not included. Can't be used in conjunction with any other offer.